Fuzzy Studio

Intuitive no-code robotic programming and simulation

- Visual no-code robot programming and simulation

- Designed for people who are not robotics experts

- Compatible with all major robot brands

- Enables both offline and online robotic programming

Program any robot - no coding skills necessary

There is no need to learn or understand programming to use a robot. With our no-code user interface, visually interact with the 3D simulated environment and the robot programs are automatically generated for you. Get up and running right away without wasting time on details. Figure out how robotics can work for you with step-by-step application tutorials and our clear user interface.

Design and simulate your robotic workcell

Design, simulate and modify an entire robotic process in just a few clicks. In Fuzzy Studio, anyone can layout, test, and reconfigure their robotic workcell. Checking for reachability, collisions, and cycle-time help you refine your project in simulation easily and derisk your robotic investments. If you already have a workcell, model it in Fuzzy Studio to give yourself a fully functioning digital twin for offline programming.

Generate trajectories from CAD

Using Fuzzy Studio’s intelligent trajectory generation tools, you can automatically generate complex trajectories for your process directly from the 3D parts in your scene. Fuzzy Studio provides a powerful arsenal of trajectory generators that understand your CAD and/or 3D models and transform hours of painstaking work into a few easy clicks. Export your trajectories for use in your robot controller or PLC, or level-up to with Fuzzy Studio Production for real-time deployment.

Works with all major brands

Control and program your robot in real-time

Fuzzy Studio’s compatibility with Fuzzy RTOS allows you to take control of the real robot. Don’t just simulate your robotic system, run it on the real deal. In one click, connect your simulation to your real system. Easily reprogram, repurpose and monitor your production system for full control.

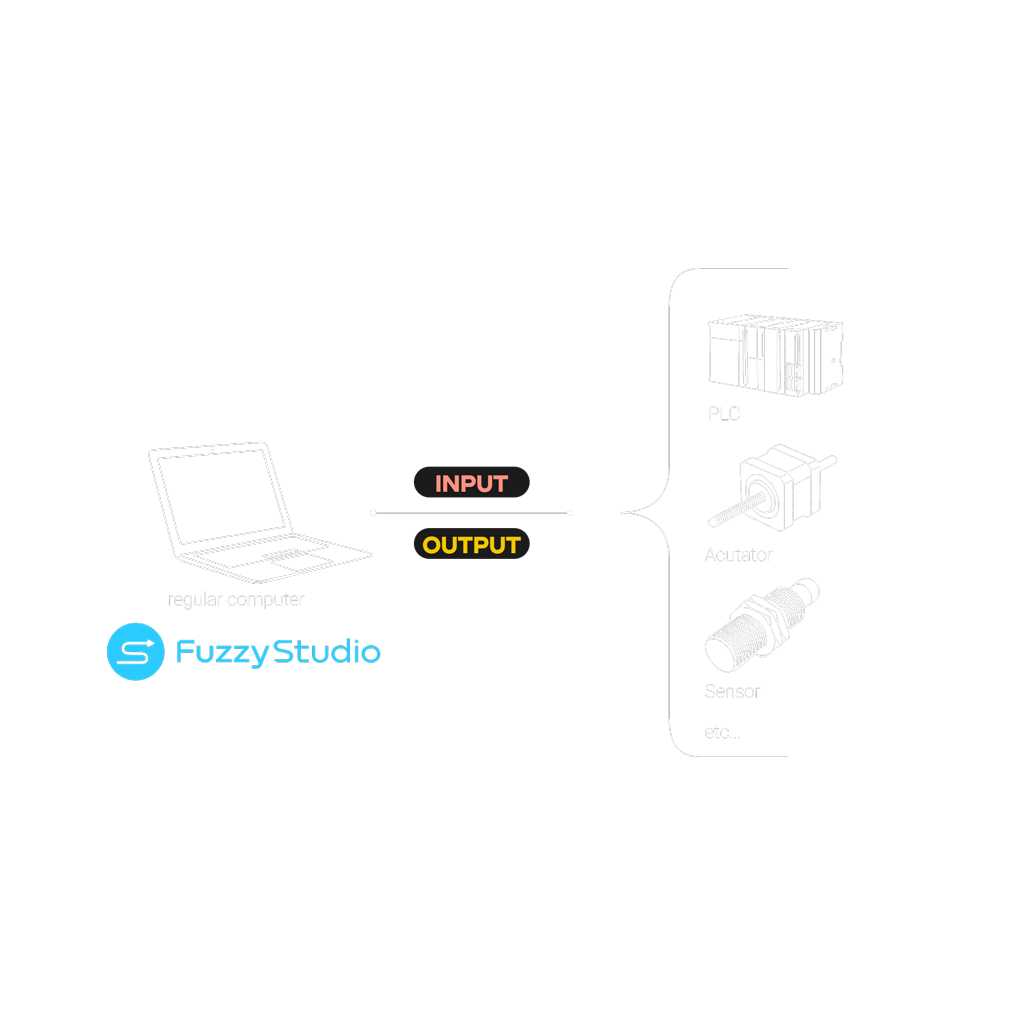

Communicate with external devices

Our I/O configuration tool allows you to easily configure software I/O (Input/Output). This enables your robot to communicate with the different elements of its work cell. They can be used to send and receive information with external devices, such as sensors, actuators, PLCs, and other software. Once configured, I/O can be used during the execution of a trajectory to send and receive information in real time.

Visually automate any robotic process

Coming soon…

With the soon to come Sequencer tool, you will be able to visually design full robotic processes without a single line of code. The Sequencer will enable you to build complex automation applications in record time and without robotics or coding expertise.

Minimum System Requirements

Mid-range Intel Core i5

16Gb of RAM

Recent entry-level dedicated graphics card

15Gb of free Disk

Recommended SSD

Full-HD screen (min)

Windows 10-11

Control all major brands of robots

with one interface.

Use advanced control algorithms for any robot

Connect easily with modern and universal interfaces (MQTT, REST)

FAQ

Frequently Asked Questions

Yes! But it is also an Online Programming (ONP) software. This means that you get the best of an OLP software (added productivity, no production stoppage) with the rapidity and flexibility of no-code programming directly on your real robot and no brand specific interfaces.

No. Fuzzy Studio only supports 6 Degree of Freedom (DoF) industrial polyarticulated robots and cobots for the moment. Please let us know here if there is a particular type of robot you need to simulate.

Not today but pretty soon! Support for external axes will come in Q3-Q4 2023. Feel free to let us know here if you have any particular requests or ideas.

Nope. Working in simulation gives you far greater freedom and precision in creating robot movements. What is critical is being able to calibrate the real world environment with your simulated environment. Check out this tutorial for more information.

Not today but soon! Path planning is the process of determining a collision free path through space for the robot. Our R&D department is brewing up some killer path planning features for future releases and more news will come as we begin beta testing in 2023. Sign up for the newsletter to stay informed about all new and upcoming features.